That was an aggressive start to this. Let me try that again.

I've got a lot of belt buckles, and an odd collection at that. Some, I bought for myself, some were given to me as gifts. The collection includes, among many others, a soviet hammer and sickle, an M1A1 Abrahms tank, Captain America's shield, a functional iPod Video case, the obligatory and rarely-used flask, and an actual, vintage NES controller, complete with a cigarette burn from its life as an actual controller in the 80's. They range from subtle and cool to what can be generously be referred to as "a bit much."

Is this important? Not yet. I didn't make that stuff. I'm getting to the making mistakes part.

A while back, I had some time off stored up. I needed to use it, but didn't have vacation plans. I needed something to do. "You mean, like forming a lifelong bond with your infant son?" Yeah, but I mean, babies sleep a lot.

So I started making buckles like a crazy person.

That's one way to start. I mean, I can wear it to work and that's almost the only place I go, so it makes enough sense. Cool.

So I started making buckles like a crazy person.

|

| It begins. |

This one, I did a lot of extra work to create, as you can imagine for a first run. For starters, that buckle base used to be a Green Lantern belt buckle. Having never been a fan of Green Lantern (or most of DC comics outside of Batman, Flash, and Martian Manhunter), I decided this was a great donor. The buckle was made up of a metal dish, basically, with a GL logo in the bottom, and then it was just filled with green resin.

So. Step one was to explode that resin. I went to town with a hammer and chisel and got it all out of there without damaging the metal. Pretty easy, and after a little while, it was coming out in big chunks.

Next, I took dimensions. The inner diameter was roughly 78mm, so I designed the Best Buy logo on a round base of 77.5mm, factoring in a little sloppiness in the print. This turned out to be a great fit, no issues.

Now. At this point, it's important that you understand that at this point in my 3D printing journey, I was not great at designing. I was using Microsoft 3D Builder, which is a severely limited application, though one I appreciate being free. I was also only buying filament one spool at a time. I would pick a color and just order a spool and use it until it ran out. I was like a stupid caveman in a lot of ways. That means I printed this buckle thing in whatever random color was lying around and then HAND PAINTED IT. That's nutty. But that's where I was at that point.

I started off with oil paints. Why? Because I had oil paints and thought it might look cool. Did it?

|

| Uh. No. Not really. |

Alright. Not great. Maybe I'll fix that later. On top of not looking right, and the white somehow being a dark gray, the paint wasn't drying at all. I wanted that cool visible brush stroke look, and apparently, it takes up to several weeks to dry. Gross.

Let's try again with acrylic paints.

|

| Oil paints, I hope you understand that this is definitely personal, and you suck. |

Bam. So. There's the finished product, basically. Pop that into the base with a little E6000, and all is golden.

But I wasn't done. I wanted to do more. Many more. But I didn't want to keep buying Green Lantern buckles (don't want anyone thinking he's legitimately popular as a hero or a buckle).

|

| Well, hello to you. |

So I found blanks. And then...

|

| So much production. |

At this point, I was cranking out new designs, and spending my evenings just casually painting things. It was kind of relaxing, in a way.

It was also a stupid amount of work. I had at this point added a second 3D printer, toyed around with another several slicers, and upgraded from working in Microsoft 3D Builder to working in AutoDesk 123D Design. Yes, you are free to tell me that I'm dumb for not using Fusion360. No, I will not drop everything to go learn Fusion360 right now.

Using 123D Design, making parts that fit together mechanically is significantly easier. So I had the idea of creating a new buckle "system." I'd make a baseplate with the buckle itself, and then little inserts I could swap out anytime.

|

| Home base(plate) |

By working this way, I could accomplish a few things.

1. Blank belt buckles are expensive (~$5 apiece), so making more than a few for myself would be crazy.

2. Instead of painting all these pieces, I could make multi-color prints on the inserts through filament swapping.

Let's talk about that second thing. By using Prusa Slicer, I can tell the slicer to insert a filament swap at a given layer. So by making each color element a different height when designing, I can easily print in as many colors as I have available. Coincidentally, this is when I started buying multiple spools of filament at once in as many colors as I could get my hands on.

I started off with the Guardians of the Galaxy print. It's a simple two color. Easy start. I then moved on to the Avengers, which is actually a 3 color, with the third being the black outline.

I was getting more confident, since those turned out so great. I started getting more complex, and more precise. If I was going to be printing at 0.2mm layer heights, then in the design stage, I can determine how many layers of each color to print. Doing three or more colors isn't so daunting now. Let's make more Marvel stuff!

At this point, I had a pretty solid collection. And they look good! I just need someplace to put them, because they're just all over the table.

Awesome. Little box for my buckles. And it's the perfect size for all of them. Great. Done. Awesome job, everybody.

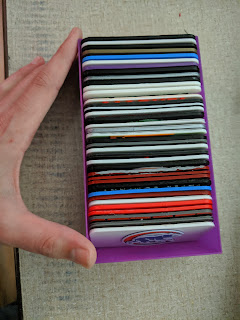

Okay. That's more. That's a lot more. Those won't fit in the box.

Yep. New box. Designed it myself just to hold my obsession.

By the time all was said and done, I'd gone well over a month without wearing the same buckle twice. It was time to bring it back around full circle.

If you're interested, you can buy your own fully custom belt buckle at KenMakesStuff.com. Just added these to the store last night, in fact. I started off with many mistakes, and ended with a pretty legitimate product. Vacation time well spent.

Awesome. Little box for my buckles. And it's the perfect size for all of them. Great. Done. Awesome job, everybody.

Okay. That's more. That's a lot more. Those won't fit in the box.

Yep. New box. Designed it myself just to hold my obsession.

By the time all was said and done, I'd gone well over a month without wearing the same buckle twice. It was time to bring it back around full circle.

If you're interested, you can buy your own fully custom belt buckle at KenMakesStuff.com. Just added these to the store last night, in fact. I started off with many mistakes, and ended with a pretty legitimate product. Vacation time well spent.

No comments:

Post a Comment